Armarator

New-gen battery separator with uncompromised performance and durability for high-power and high-safety battery solutions

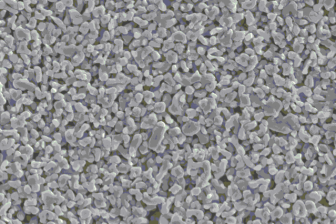

Armarator is a proprietary-design separator that offers a number of advantages over traditional separators. It has superb high-temperature mechanical strength up to 250°C, which makes it ideal for use in high-power batteries that have exacting high-safety requirements. With low direct current internal resistance (DCIR), Armarator is less likely to cause battery degradation. It is capable of high-speed winding and stacking, and accommodates the demands of mass production at scale. As it does not require modifications to existing production processes, Armarator is easy for seamless adoption as a cost-effective solution for battery manufacturers.

The future of electric transportation, elevated —Armarator is ideal for use in a variety of battery applications where superior, uncompromising performance is crucial. These include next-generation capabilities for electric vertical take-off and landing (eVTOL), unmanned aerial vehicle (UAV), and hybrid electric vehicle (HEV) mobility solutions.

The future of electric transportation, elevated —Armarator is ideal for use in a variety of battery applications where superior, uncompromising performance is crucial. These include next-generation capabilities for electric vertical take-off and landing (eVTOL), unmanned aerial vehicle (UAV), and hybrid electric vehicle (HEV) mobility solutions.

Product Categories

Features

Features

ArmaratorTM has the following advantages.

- Superb high-temperature mechanical strength up to 250°C.

- Low DCIR in battery systems.

- Can integrate with high-speed winding and stacking.

- No production process modifications required.

Testing videos

Fire resistant test

- High endurance — ceramic framework structure ensures Armarator™ keeps going strong unlike commercial separators (PE with double-sided coating) that break down under high temperature.

Heat shrinkage test (w/ electrolyte)-Adhesive Function

- Aramarator™ maintains its structural integrity after burning and shows no cracks even at 250°C Celsius.

Winding processes

- Armarator™ performs smoothly during high-speed winding process, and can be applied to a battery maker’s existing manufacturing setup without the need to make modifications.

Internal short circuit test

Tensile strength test (after baking)

Water Content Test

Nail penetration test

- Armarator™ expansion hole size is smaller than a commercial separator in th nail penetration test.

Capillary height test

- Armarator™ exhibits enhanced compatibility with the positive and negative electrode liquids within the battery, facilitating improved integration.

Compression retention test

- Armarator™ pore diameter is compressed by 10% less than that of a commercial separator.

Puncture Strength Test

- Armarator™ exhibits enduring flexibility in the puncture process, showcasing retained resilience even after exposure to high-temperature baking, distinguishing it from standard separators.

Thermomechanical Analysis(TMA)

- Armarator™ stands strong after a 300°C Temperature Test, While conventional separator films have already split.

Specifications

| Commercial separator | ArmaratorTM | ||

| Thickness (um) | 12 | 12 | |

| Gurley (sec/100c.c) | 97 | 77-200 | |

| Heat shrinkage (250°C@1hr) | Breaks down | <5% | |

| Melt Integrity(TMA) | 147 | 330 | |

| Adhesion with the electrode | - | YES | |

Applications

An original-design separator ideal for high-safety and high-power battery applications used typically in eVTOL, UAV, HEV solutions, and more.

Related Products