BenQMaterials

Products

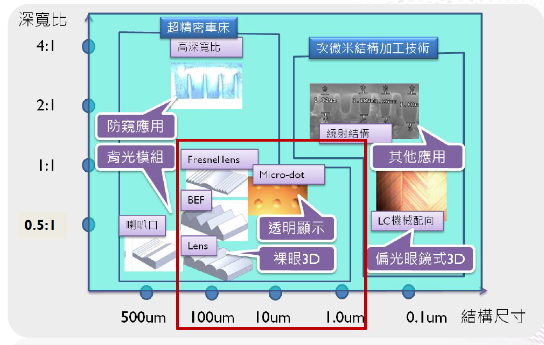

Display Tech and Materials

Ultra-Precision Machining

Various Display Applications

Various Display Applications

Provide customized molds and large width molding solutions

Especially for the mold processing and molding process development of optical prototype components, it provides the optical structure required by customers, changes the optical path, corresponds to various applications of large-size curved displays, and provides naked-view 3D solutions to meet the needs of the end market.

Product Categories

Features

Features

Sturcture:

BenQ Materials' patented microstructure processing and molding technology is an application through substrate and UV processing. In addition to providing solutions with polarizer projects, processing options are also available.

Processing projects include "one-dimensional distribution structure, two-dimensional distribution structure, micro-groove application, multi-angle processing technology, appearance parts processing" and many other applications, changing the visual effect of the display, in the anti-peeping requirements of the vehicle display, anti-reflection of the general display, solving The large-view role and the demand for curved displays play a key role.

Certification

| Save environmental conditions | Save time | |

| Temperature | 20°C±10°C | 6 months |

| Humidity(%) | 65%±15% | |

| Project | Test Results |

| Grid | pass |

| Hardness | H以下 |

| RA(500H) | YI |

| 60°C/90% | ≤10 |

| 80°C | ≤10 |

| -40°C | ≤10 |

| 85°C/85% | ≤10 |

eye 3D solution

Structure:

It is made of Lenticular Lens Film through optical design, through precise engraving → curing molding → cutting → lamination

Features:

Can be designed for panel specifications, resolution PPI, required size, pixel arrangement, viewing distance, and desired number of layers

Existing Finished Applications:

Eye Tracking Naked Vision 3D Display

- Size:10.1”

- Panel resolution:1920x1080

- View number 2view+Eyes tracking

- Real time rendering 3D image

- Can be integrated with touch

Naked Vision 3D Ordering Machine

- Size: 15.6”

- Panel resolution: 1920x1080

- Number of Views: 9views (recommended for single use)

- Other functions:

- Capacitive floating touch (Single touch): 3~5cm, waterproof

Terminal application naked 3D photo frame

- Size: 7.9”

- Panel resolution: 4K

- View number 49view (holographic)

- Other functions:

Application

| Specification | PC film | PC film + UV glue |

| Thickness | 125um | |

| Effective width | 730mm | |

| Refractive index | 1.6 | 1.5785 / 1.6162 / 1.6495 |

| Specification | PMMA film | PMMA film + UV glue | |

| Thickness | 40um | ||

| Effective width | 1.5 | ||

| Refractive index | 1.5 | 1.51 | |

| N1+N2 (UV) | 1.61+1.51 | ||

| Specification | PET film | PET film + UV glue | ||||

| Thickness | 100um | 125um | 188um | 100um | 125um | 188um |

| Effective width | 1000um | 900um | 900um | |||

| Refractive index | 1.6 | 1.6 | 1.6 | |||

| low refractive index | 1.5 | |||||

| high refractive index | 1.5785 / 1.6162 / 1.6495 | |||||

| N1+N2 (UV) | 1.6162+1.5 / 1.6495+1.5 | |||||

3D Lenticcular

| Application | Machining | forming technology |

| Mobile | 4.7"、5.8" | Lens Direct Engraving Mould Double layer UV glue forming |

| Display | 15.6"、27"、65" | Lens Mold Single/double layer UV glue forming |

| Kanban | 65"、85"、98" | Seamless Dies Single/double layer UV glue forming |

背光模組

| Application | Machining | forming technology |

| Display | 15" | Curvature diamond lens Single layer UV glue forming |

| Display | 17" | MicroDot Straight Machining Single layer UV glue forming |