BenQMaterials

Products

Display Tech and Materials

Industrial Tape

Semiconductor and Display industry Applications

Semiconductor and Display industry Applications

Semiconductor and panel industry applications. Diverse solutions for optimal substrates and adhesives

BenQ Materials provides customizable solutions, including PE/PET protection film, PET heat-resistant double sided tape, and ACF. With different combination of base materials and adhesive materials, diverse solutions can be offered to meet various customer demand.

Product Categories

Features

Features

BenQ Materials' industrial tape manufacturing process covers "roll-to-roll" and "injection-extrusion" processes in six core technologies, and provides optical-grade excellent protective release film for PE, CPP, film, PET and other product projects, and has good adhesion, It is not easy to produce air bubbles, high cleanliness and release quality. Customized and diversified substrate thickness and adhesive force selection meet the needs of customers' production environment. The photosensitive solder resist has no glue residue and can be removed again, suitable for mass production and easy to clean; Provide release film with different thickness specifications (19um, 38um).Using high-transparency substrates and high-transparency adhesives ensures high light transmittance in a wide wavelength range over 300mm.

Features:

- Low crystal point

- High adhesion stability

- High transmittance and low haze (TT>92%, Haze<2%)

- Temperature resistance plus

- No glue residue

- Good adhesion

- Not easy to generate air bubbles

- High cleanliness

- Release stability

- Residual followed by 99%

Sturcture:

- PE Protective Film

- Three-layer co-extrusion process

-

▲ PE保護膜產品

-

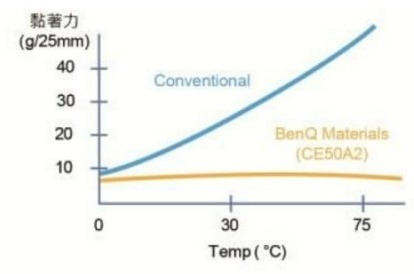

▲ PE保護膜黏著力表現

-

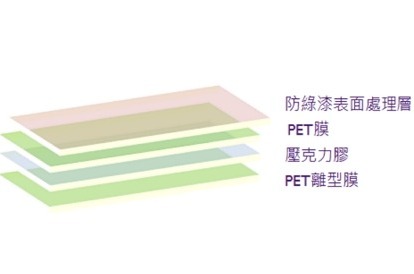

▲ 菲林保護膜產品結構

-

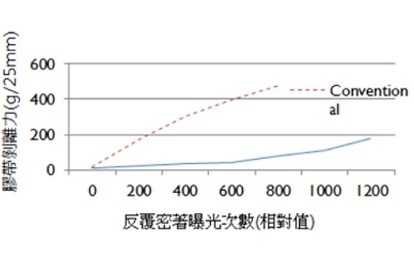

▲ 菲林保護膜剝離

-

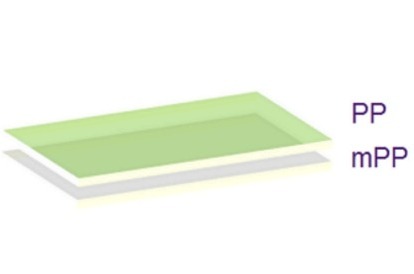

▲ CPP保膜產品結構

▲ CPP保膜產品結構

Specifications

| 應用 | 半導體應用 | 玻璃業應用 | 顯示器應用 | |||

| 型號/規格 | CE50A2 | CE40R4/CE60R4/CE80R4 | CE80Z1 | CEL-10R | PB10-R0 | PB38-L0 |

| 顏色 | 透明 | 霧 | 霧 | - | 透明 | 透明 |

| 總厚度(um) | 50±3 | 40±3/ 60±3/ 80±5 | 80±5 | 35±4 | 19 | 38 |

| 幅寬(mm) | 1300±10(max) | 1600(max) | - | - | <2050 | <1350 |

| 長度(M/RL) | 200±10 | 200-1000 | 200-1000 | - | 3800-6000 | 3800-6000 |

| 黏著力/離型力(fg/25mm) | 5±2 | 30±10 | 400±50 | To SUS 200±100 | 15-25 | 5-10 |

| RA Test | 75°C,75%,120 hr | 150度、30Mins | 150度、30Mins | - | - | - |

| 殘餘接著力(%) | - | - | - | - | 99% | 99% |

| TT(%) | >92% | - | - | - | >90% | >90% |

| Haze(%) | <2% | - | - | 2% | <5% | <5% |

| Total Light Transmittance | - | - | - | ≧91% | - | - |

| Transmittance(330mm) | - | - | - | 98.5% | - | - |

| 基材厚度(um) | - | - | - | 6 | - | - |

| 黏著層厚度(um) | - | - | - | 4 | - | - |

| 應用能力 |

|

|

|

|

|

|