OCA

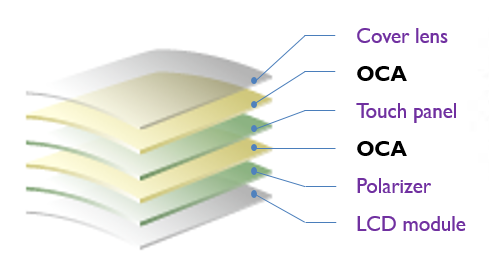

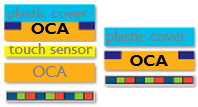

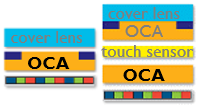

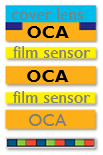

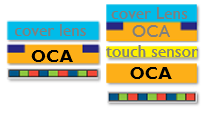

Sturcture:

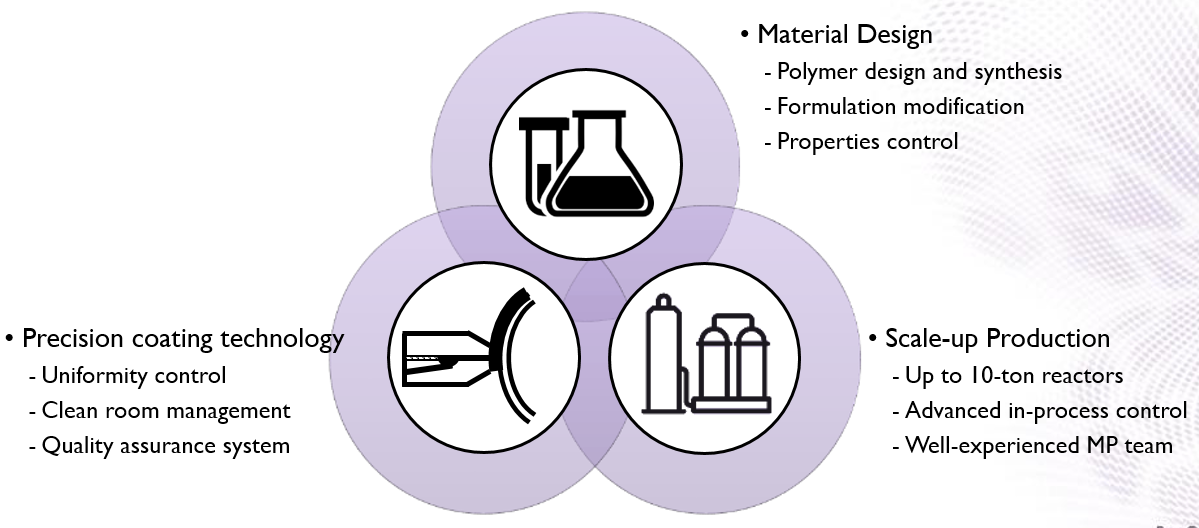

OCA adhesives (Optically clear acrylic adhesives) are key materials for touch panels and displays independently developed by "polymer synthesis" among the six core technologies of BenQ Materials. It has excellent optical clarity, high adhesion, high weather resistance and no acid etching. Low corrosiveness to ITO and excellent filling properties. With the full lamination process, the brightness, contrast and visibility of the display screen under strong light can be greatly improved.

BenQ Materials currently has products such as full-laminated optical adhesives, plastic-board laminated optical adhesives, low-dielectric optical adhesives, automotive/high-weather-resistant optical adhesives, and integrated black optical adhesives, which correspond to smart life applications such as in-vehicle, mobile, home and work.

The whole series of BenQ materials OCA adhesive adopts a solvent-free coating process, no harmful solvent volatilization, no VOC and other compounds residues, and meets the low-carbon emission requirements. The whole process of low temperature UV LED light curing process, rigorous high energy efficiency and fast curing, is superior to traditional high pressure mercury lamps, improves production efficiency, and is in line with high energy efficiency, non-toxic, environmentally friendly, and green chemical products that react at room temperature and pressure.

- Good level difference filling performance, no rebound bubbles.

- Good weather resistance, no yellowing (high temperature 85℃, high temperature and humidity 85℃/85%RH, >500 hours)

- Prevent PC/PMMA plastic board from outgassing and foaming at high temperature

- Low dielectric (Dk < 3.0 @100MHz), effectively improving the operating sensitivity of the cover-integrated touch panel.

- 250~365nm UV blocking, effectively prevent the display screen from being degraded by UV light.

- Resistant to solar radiation, in line with DIN 75220 automotive specifications.

- Low storage modulus, effectively preventing the panel from sticking to Mura.

- Customizable penetration rate (50%~90%), perfect integration of screen black effect.

- 250~365nm UV blocking, effectively prevent the display screen from being degraded by UV light.

- Resistant to solar radiation, in line with DIN 75220 automotive specifications.

| Product | B1 series | B2 series | B3 series | B5 series | |||

| B123 | B201 | B221 | B303 | B501 | B502 | B503 | |

| Application | E-book Automotive |

Mobile Tablet |

Mobile Tablet |

Tablet NB |

Automotive | ||

| Structure |  |

|

|

|

|

||

| Non Solvent | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ |

| Non UV | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ |

| Low Acid | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ | ☉ |

| PMMA/PC Compatible | ☉ | - | - | - | - | - | - |

| Step Coverage | - | ☉ | ○ | ☉ | ○ | ○ | ○ |

| Low DkValue | - | - | - | ☉ | - | - | - |

| UV cut off | - | - | - | - | ☉ | ☉ | ☉ |

| Integrated Black | - | - | - | - | - | ☉ | - |