Architecture Use

Sturcture:

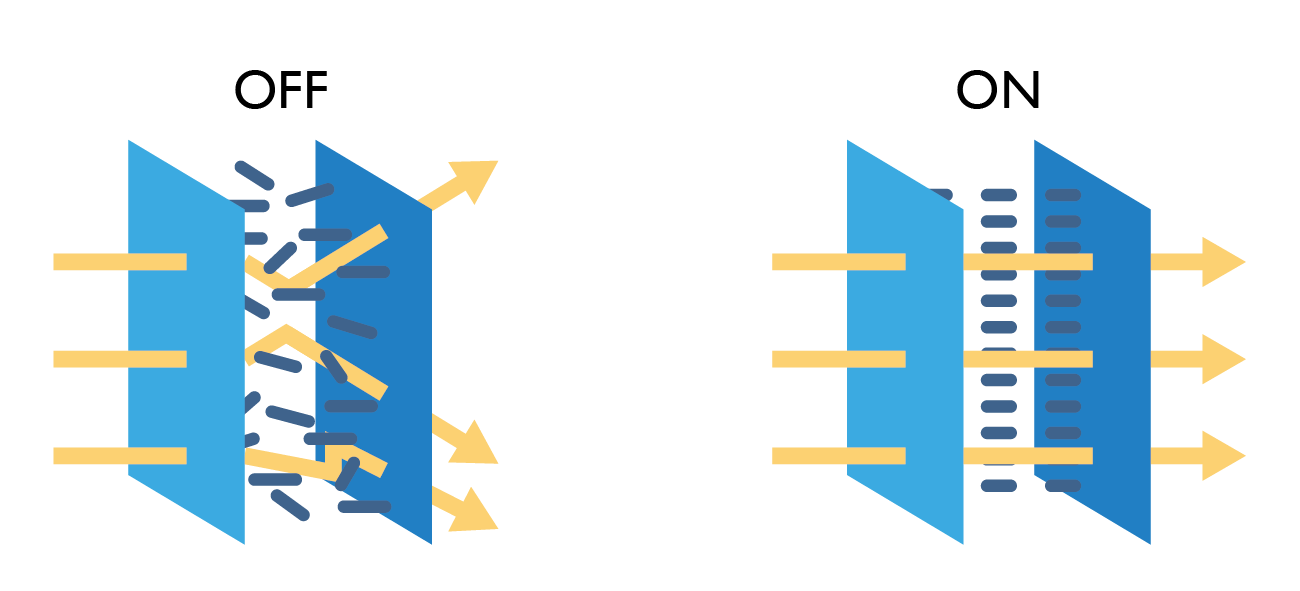

The current product structure offers "adhesive" and "laminated" film. The adhesive film is suitable for renovating existing interior space on glass or acrylic depending on needs, while the laminated film is suitable for new space as it combines the PDLC Smart Film with glass through lamination, providing better protection than the adhesive film. These two products aim to provide diverse applications in the home, mobile, as well as commercial spaces, fulfilling the needs to switch between privacy and space, providing flexible scenarios for spatial application.

The adhesive film is suitable for renovating existing interior space on glass or acrylic depending on needs, while the laminated film is suitable for new space as it is laminated on glass, providing better protection than the adhesive film.

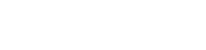

When the power is switched on, the liquid crystal polymers are neatly arranged, allowing the light to penetrate evenly, showing clear-glass-transparency. When the power is switched off, the liquid crystal polymers are irregularly arranged with light scattered in all directions, showing frosted-glass-matte effect.

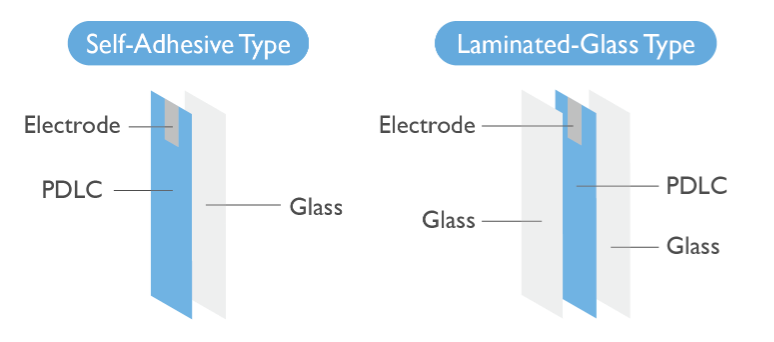

BenQ Materials PDLC Smart Film possess characteristics including second-to-none translucency and lower energy consumption. To fulfill our corporate core strategy - "achieving the true beauty of technological life", while developing material science, BenQ Materials is dedicated to making efforts towards the environment, hence the development of "the world's first green building material - PDLC Smart Film".

Thanks to its special manufacturing process verified by the green materials verification laboratory, the PDLC Smart Film can block 99% of UV and 87% heat, effectively reducing the energy consumption of home appliances. Our product is designed for the application of converting space transparency and privacy, further achieving the twin benefits of energy saving and carbon reduction.

As BenQ Materials PDLC Smart Film consumes very little energy and effectively blocks heat, adequate lighting can penetrate the room, reducing the consumption of air conditioning and carbon, making it the best option for sustainability.

As the PDLC Smart Film is made through a complex process, we must send our PDLC products to a testing & verification platform endorsed by national standards agencies to carry out high-standard experiments and tests. Furthermore, we have also invested in a laboratory designed to simulate the actual use of the product, which requires long-term testing & verification. This approach helps us ensure that we bring energy-saving benefits to our customers. Meanwhile, the PDLC products have passed the national criteria for green building materials and have obtained the environmental label for green building materials.

▲ Our green demo house in National Cheng Kung University

▲ Actual test of the PDLC Smart Film on glass in the laboratory

-

▲ Bathroom

▲ Bathroom -

▲ Glass curtain wall

▲ Glass curtain wall -

▲ Capsule office

▲ Capsule office

| Laminated-glass Type | Self-adhesive Type | ||||

| Flim Series | PDLC 97 (WH) | PDLC 97 (WH) | PDLC 97 EX(GR) | PDLC 97 EX(BR) | |

| Thickness | 0.11 mm | 0.26 mm | 0.33 mm | 0.33 mm | |

| Operation Mode | On : Transparent / Off: Opaque | ||||

| Maximum | 1,500 mm x 3,000mm | ||||

Optical Property |

Visible Light Transmitt ance | > 87% (On) > 76% (Off) |

> 87% (On) > 76% (Off) |

> 66% (On) > 58% (Off) |

> 36% (On) > 31% (Off) |

| Haze | < 4% (On) > 97% (Off) |

< 4% (On) > 97% (Off) |

< 5% (On) >97% (Off) |

< 5% (On) >97% (Off) |

|

| View Angle | 160° | ||||

| UV-cut | 17% | 98% | 99% | 99% | |

| IR-cut | 60% | 60% | 87% | 87% | |

| SHGC (Solar Heat Gain Coefficient) | - | - | 0.49 (On) 0.40 (Off) |

0.38 (On) 0.32 (Off) |

|

Electncd Property |

Operation Voltage | 48V (AC) | |||

| Frequency | 50 ~ 60 Hz | ||||

| Power Consumption | 5-10 W/m² | ||||

| Response Time | Off to On :< 10 ms / On to Off :< 200 ms | ||||

| Operation Temperature | -10 ~ 60°c | ||||

| Storage Temperature | -20 ~ 65°c | ||||